Sustainability

Our commitment to reducing environmental impact

At Hiro, we believe that design can and should be sustainable. Our commitment to the environment accompanies us through every stage of the production process, from choosing materials to shipping to your home.

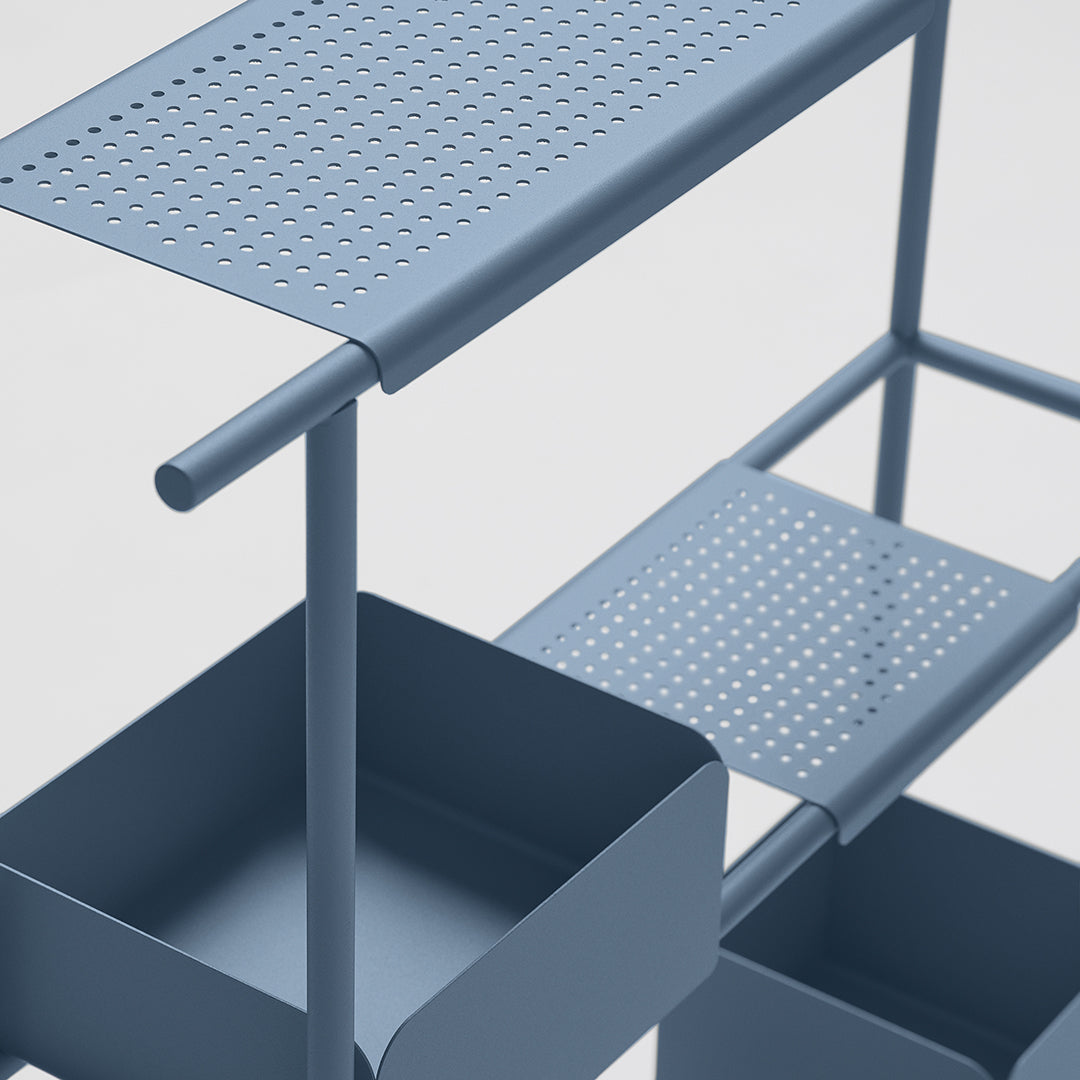

Materials and the circular life cycle

The high-quality design and use of durable materials ensure that each piece will stand the test of time. This not only reduces the need for frequent replacements but also promotes more responsible consumption.

The main material of our products is metal , which is infinitely recyclable without losing quality. Each product can be reused, repainted, or disposed of, remelted, and transformed into a new product of equal quality, giving it a new lease of life .

The wood used in our products is a mixture of at least 90% recycled wood, the remaining 10% comes from virgin processing waste or from FSC-certified sustainable forests . This endless recycling cycle helps reduce pollution and conserve natural resources.

See the productsResponsible production

Our sales cycle requires minimal inventory, in some cases zero. We produce virtually on demand , following market demand and producing it as needed.

This process contrasts with the more widespread practice of producing large quantities of products to lower prices and then releasing them onto the market in order to dispose of what has already been manufactured, resulting in greater waste of resources and the production of scrap and waste.

Empowering the end consumer

Our philosophy of involving design lovers and end customers in the product selection and manufacturing phases, as well as ensuring a shared design , goes in the direction of building only what is actually needed and not something that has been arbitrarily imposed by some strategic choice before consulting with the end customer.

Production in Italy

We manufacture everything we sell entirely in Italy. This ensures compliance with high environmental standards throughout all production phases. We are constantly committed to reducing the environmental impact of our production. We use advanced technologies to minimize waste and energy consumption in the production process.

Photovoltaic systems are mounted on the roofs of our workshops, partially covering the company's energy needs, ensuring that every stage of production is as eco-friendly as possible.

Made in Italy

Eco-friendly packaging

We are committed to constant research to minimize the use of plastic and to better protect products during transport with recycled and recyclable materials , especially paper and cardboard.

The shipments

We combine as many items as possible into a single shipment . This may mean delivery takes a few extra days, but this optimizes the courier's travel, ensuring a lower environmental impact. We require our couriers to also commit to reducing their environmental impact. Currently, we primarily use two carriers: GLS and BRT.

For GLS we have joined the “Climate Protect” program, which means that for every single package shipped we pay a fee that is allocated to “forest conservation projects and the installation of systems for the production of energy from renewable sources” (to find out more click HERE ).

BRT is committed to an environmental program aimed at reducing emissions by 2030 and claims to be “the first company globally in the delivery sector to have short- and long-term CO2 emissions reduction targets approved by the Science Based Targets Initiative.” To date, it has dramatically increased the use of electric vehicles and the use of energy from renewable sources in its logistics centers ( learn more ).

Most loved by the Community

Unique pieces, 100% Made in Italy, designed to make every corner of your home special.